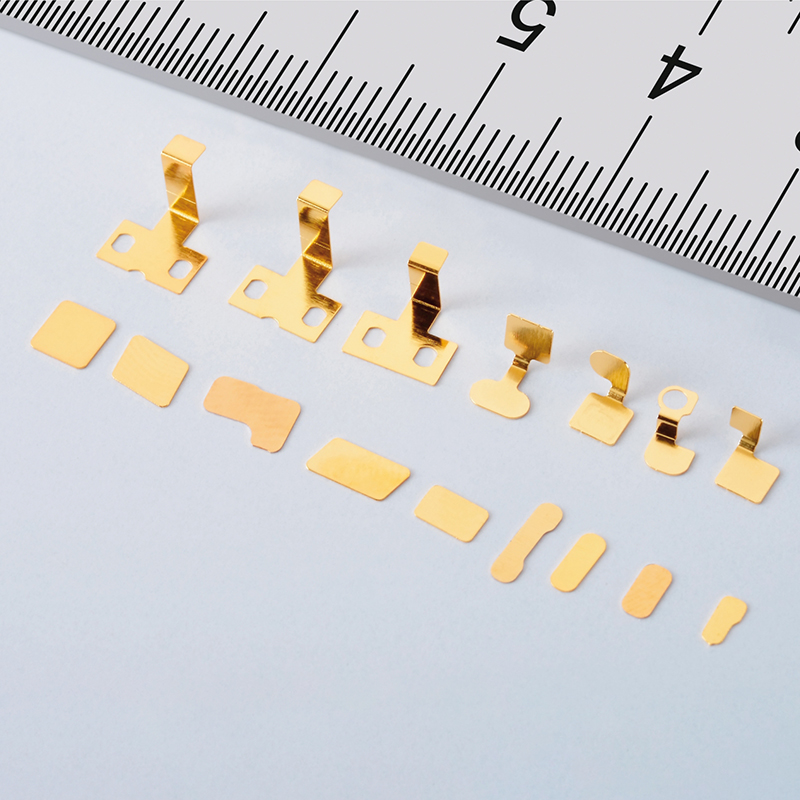

Trusted custom flat springs with different coating

Flat springs Gallery:

What are Flat springs?

A flat spring is commonly manufactured from a flat bar or strip. Types of flat springs include bow springs and cantilever springs. Flat springs are formed with an arc at or near the center and are supported on both ends with the force applied to the center of the arc. Thanks to the near-limitless customizing possibilities available when manufacturing flat springs, they can be made to fit any application you need. Cantilever Springs are made from the same materials but are clamped on one end while the force is applied to the other. These types of springs can be used as centralizers and equalizers.

Trusted custom Flat springs manufacturer

With years of experience developing quality spring products for demanding applications, AFR Precision&Technology Co.,Ltd can deliver custom flat & cantilever springs tailored to your requirements. We’re an ISO 9001:2015-certified facility with a comprehensive range of in-house design, engineering, fabrication, and value-added service capabilities.

Here’s what we are doing and what we can offer to save your time and money. :

▶ Spring Design

▶ Heat Treating

▶ Passivation

▶ Orbital Welding

▶ Tube Bending

▶ Shot-Peening

▶ Coating And Plating

▶ Non-Destructive Examination, or NDE

Specifications Of Our Flat Springs

As one of the Chinese leading flat spring manufacturers, we offer a variety of customizable specifications so you can order the perfect flat spring for your specific needs. From different material sizes, materials used and even finishes, you can ensure that you are receiving the best possible service and product from AFR Springs.

Wire Size: 0.1mm upwards.

Material: Flat spring steel, stainless steel, music wire, silicon-chrome, high carbon, beryllium-copper, Inconel, Monel, Sandvik, galvanized wire, mild steel, Tin-plated wire, Oil-Tempered Spring Wire, phosphor bronze, brass, Titanium.

Ends: there is a wide variety of end types that can be put on a wire form spring including machine loops, extended loops, double loops, tapers, threaded inserts, hooks or eyes at various positions and extended hooks.

Finishes: Various coatings include but not limited to Zinc, Nickle, Tin, Silver, Gold, Copper, Oxidization, Polish, Epoxy, Powder coating, dyeing and painting, Shot peening, plastic coating

Order/Quote: A drawing or sample will be required in order to provide you with a quotation. Drawings can be sent by fax, post or by email to info@afr-precision.com.

Common uses of Flat springs

Flat springs are commonly used as electrical contacts – as spacers or grounds. During post-production, manufacturers add coatings to enhance corrosion resistance and electrical conductivity.

By combining a flat coil spring with a counterweight, it can be utilized to regulate the action of valves, making it suitable for vehicle exhaust systems. Flat compression springs are present in seats to provide the necessary support and leaf springs are ideal for oil and gas centralization systems. There is a broad range of materials used to manufacture flat springs to meet intended applications. The shape and size variations are unlimited, and there are different choices for finishes for all types of flat springs.

▶ Oil & Gas

▶ Mining

▶ Nuclear

▶ Marine

▶ Solar & Wind

▶ Transportation

▶ Aerospace

▶ Automotive

▶ Valve

▶ Military